|

PTCOE's Capabilities at Georgia Tech |

![]()

| PTCOE has advanced thin-film deposition facilities which

include CVD, electron beam and sputtering systems, MBE/VPD and a large-area

Ion Assisted Deposition (IAD) systems. PTCOE's research faculty have extensive

experience in the deposition of inorganic materials by metalorganic and

molecular beam epitaxy as well as e-beam and thermal evaporation processes.

These systems have been used to deposit all types of materials such as

SrS:Cu,Ag, SrS:Ce, ZnS:Mn, CaS:Cu, SrGa2S4:Ce, LaO2S:Tb,

GdO2S:Tb, Si, InAlGaAsP, HgZnCdTe for displays and optoelectronic

device applications. These deposition capabilities are complemented by

insitu control and characterization techniques such as reflectance, reflection

high energy electron diffraction, residual gas analysis, quadrupole mass

spectrometry and auger electron spectrometry. Also, growth enhancement

capabilities are available including photoassisted deposition and ECR plasma

sources.Extensive expertise in the optical and electrical doping of these

materials has been developed. PTCOE's deposition systems have the capability

to handle low and high vapor pressure materials using conventional solid

source evaporation, valved crackers and gas sources (organometallics and

high pressure gases). In addition, several unique delivery systems have

been developed, which allow precise control over very high vapor pressure

materials and gas sources with control of flows over 6 orders of magnitude.

PTCOE's large-area IAD system allows the simultaneous co-evaporation

of four materials (thermal and electron beam) and the low temperature deposition

of high quality oxide materials.

Summary of IAD Capabilities

|

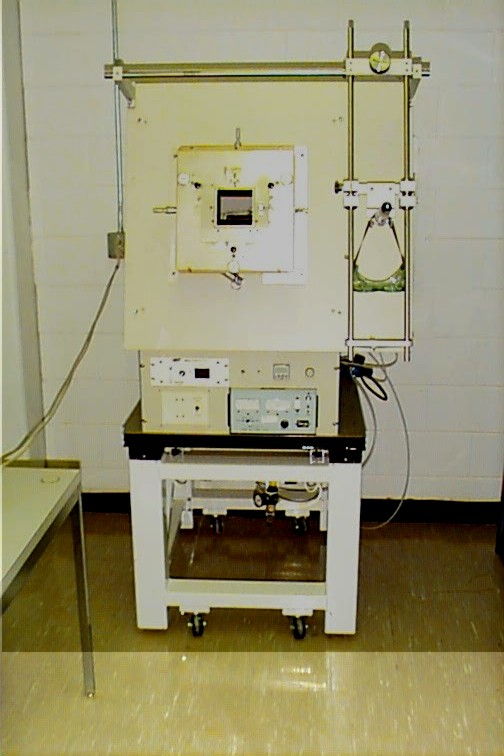

Molecular Beam Epitaxy (MBE) System used for deposition of novel EL phosphors

|

|

|

|

| To assess the quality of material layers, a variety of

material and surface characterization techniques are available. The capabilities

include Photoluminescence (PL), PL Excitation Spectroscopy (PLE), Charge

Deep Level Transient Spectroscopy (QDLTS), Secondary Ion Mass Spectrometry

(SIMS), Scanning Electron Microscopy (SEM), and X-ray diffractometry. Other

analytical instrumentation a Transmission Electron Microscope (TEM), an

Atomic Force Microscope (AFM), and X-ray crystallography equipment.

PTCOE's Automatic System of Materials Electrical Characterization (ASMEC) was specifically designed for electrical & photoelectric characterization of dielectric and wide gap semiconductors such as CaF2/ZnS/SrS. It uses powerful techniques such as Q-DLTS and Photo-stimulated Internal Field Transient Spectroscopy (PIFTS) to provide information on bulk/interface trap activation energies and capture cross sections, as well as trap concentration.

|

The photoluminescence spectroscopy system can be used to achieve above bandgap and direct excitationby deep- and/or mid UV lasers, a Xenon arc lamp and a Deuterium arc lamp. The resulting luminescence is analyzed with the detection system and provides information on the crystalline quality and impurities. In addition, a tunable light source allows PL excitation spectroscopy, which can be used to investigate the excitation mechanisms and the electronic structures of the luminescent centers in semiconductors. The dynamical properties of the luminescence such as excitation energy transfer can also be investigated by using pulsed lasers.

LIGHT SOURCES

|

| To obtain accurate cathodoluminescent (CL) intrinsic efficiency

measurements, both the reflected and transmitted light components are measured

by employing a two-photometer system. This procedure provides an accurate

correction for the transmitted emission losses of different phosphors.

Both photometers sample the same excited area within the e-beam spot. A

Faraday cup is also used in the sample holder to determine the e-beam current

before the measurement. A fast response EFG-7F e-gun with a range from

0-5 kV is used for these measurements. The vacuum system has two viewports

available for the two photometers. Its transport arm is centered on the

beam axis, and a guide rail (which holds the rotation angle constant as

the samples are translated) is used. The transport arm can also be attached

to a motorized translation stage. This stage can be computer-controlled

to translate the samples across the e-beam automatically, and take the

measurements. The photometer also enables the sample chromaticity to be

obtained in the same measurement. In addition, the PMT/monochromator system

can be quickly put in place to measure the CL decay time of the different

phosphors using the E-gun in the pulsed mode. Decay times down to 50 ns

can be measured.

The saturation, transient analysis, and aging studies are conducted in a vacuum chamber equipped with Fison LEG 32 (0-5 kV) and LEG 320 (1-30 kV) E-guns. The LEG 32 has been well characterized for beam size and current density. A Faraday cup at the bottom of the chamber measures and monitors any changes in beam current. The LEG 320 gun is used for high energy intrinsic efficiency measurements, and in addition, provides a means for extracting diffusion length and surface recombination parameters.

|

Cathodoluminescence Luminous Efficiency System

|

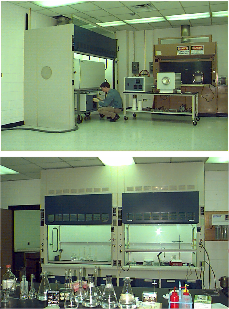

| PTCOE has access to Georgia Tech's Microelectronics

Research Center (MiRC), which is housed in a new (1989) 100,000 sq.ft.

building plus a 20,000 sq. ft. annex. MiRC includes six electronic and

optoelectronic materials labs, eight labs for microelectronic design and

testing, and eight labs for electronic device design and testing. A 7,000

sq.ft. cleanroom provides complete microfabrication facilities. Specialized

materials growth and vacuum deposition systems are also available for fabrication

of thin film semiconductor devices in a variety of material systems including

III-V and II-VI semiconductors. The photolithography area is a class 1000

room with specialized mask aligner exposure stations suitable for photolithography

into the submicron range. Other specialized equipments include surface

preparation systems and scanning electron microscopes.

Partial List of Cleanroom Equipment available at Georgia Tech's MiRC:

|

RF Sputtering System

|

PTCOE has extensive optical and electrical techniques for the analysis

and characterization of emissive and non-emissive displays as well as various

optoelectronic devices such as photodiodes and Light Emitting Diodes (LEDs).

Various computer-automated experiments are available to measure and analyze

the macroscopic & microscopic properties of thin-film heterostructure

devices. A practical probe test station has been designed and constructed

for electrical characterization measurements of optoelectronic and display

devices. Both high-voltage (150-250 V) and low-voltage (20-30 V) EL devices

can be investigated by applying unipolar and bipolar rectangular pulse

with different pulse widths. Two photometers (PR 650 & 880) are available

to measure device intensity (brightness) and CIE coordinates. A brief description

of some of these capabilities and the information they provide about the

device under test is presented in the table below.

|

Display & Device Characterization System

|

PTCOE has a suite of advanced semiconductor device simulation

tools (Silvaco's TCAD). These software packages contain both microscopic

as well as macroscopic device simulators, which provide a coupled, hierarchical

approach to semiconductor device modeling. Silvaco's device simulation

software uses powerful numerical techniques to solve for the various properties

of homojunction/heterojunction devices under different operating conditions.

A built-in optimizer allows for quick and accurate tuning of simulation

parameters. The following is an overview of the general capabilities of

Silvaco's ATLAS which includes the following tools and extensions:

PTCOE also employs Monte Carlo simulations in the analysis of CL phosphor properties, which incorporates the known physics of elastic and inelastic scattering processes for electrons incident on amorphous materials. The simulation reliably predicts range values for the primary electrons incident on the host and the electron range can be quickly calculated for many phosphors. |

Two-dimensional Electrical/Optical Simulation of an Optoelectronic Device

|